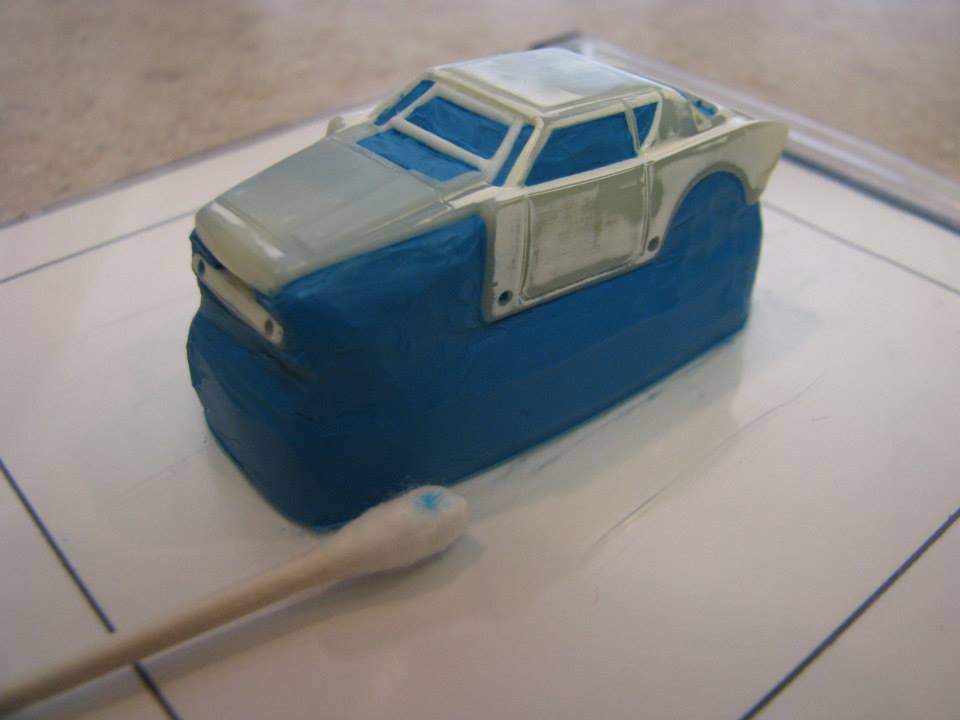

I started with a Dash Avanti body. I have never cared for the look of that car. I got to thinking how I could modify it and give it a better presentation. After some thought and consideration I thought it may look better as a dirt modified racer. I worked on the modifications smoothed, sanded, polished and clear coated the mold master.

First I clayed up the moldmaster on a clay pedestal

I take my time here... I do not rush and make sure I work clean. This is in preparation for the female mold.

After I have finished claying up the mold master, I take a Q-tip and clean the outside of the mold master. I remove all clay residue and possible finger prints. If any foreign material is on the surface, including finger prints, it will be transferred to the mold if not cleaned and removed. What this means is, if you leave a finger print on the mold master it will be transferred to all casts from that mold.

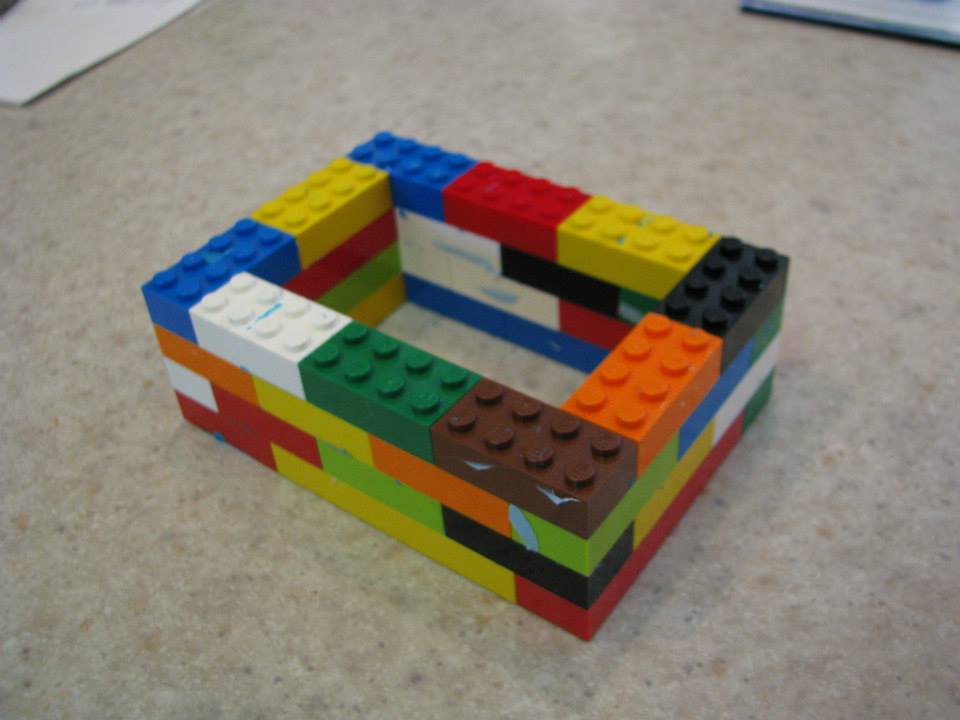

I now make my mold box. As you can see I use Legos.

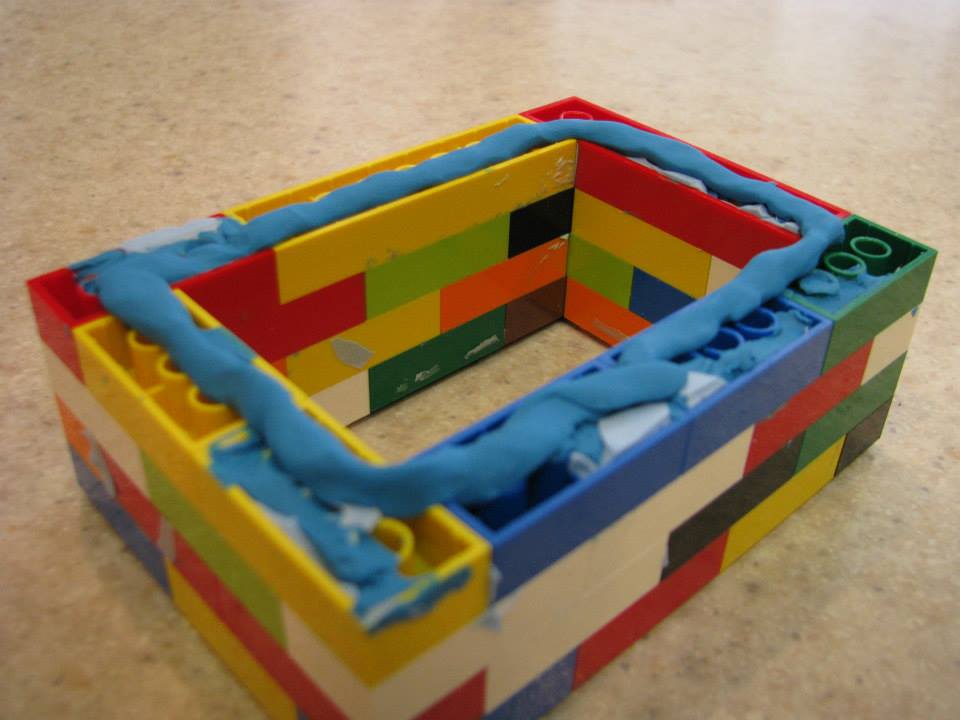

I put clay on the bottom before flipping over to prevent RTV from running out of the bottom.

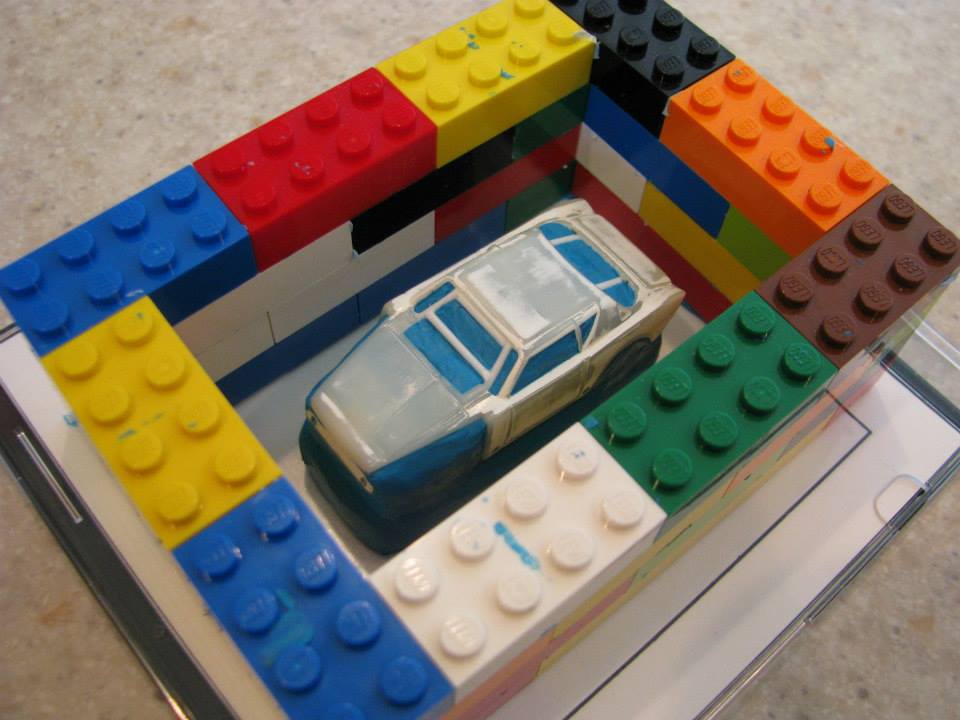

Turn the box over and center the box around the mold master.

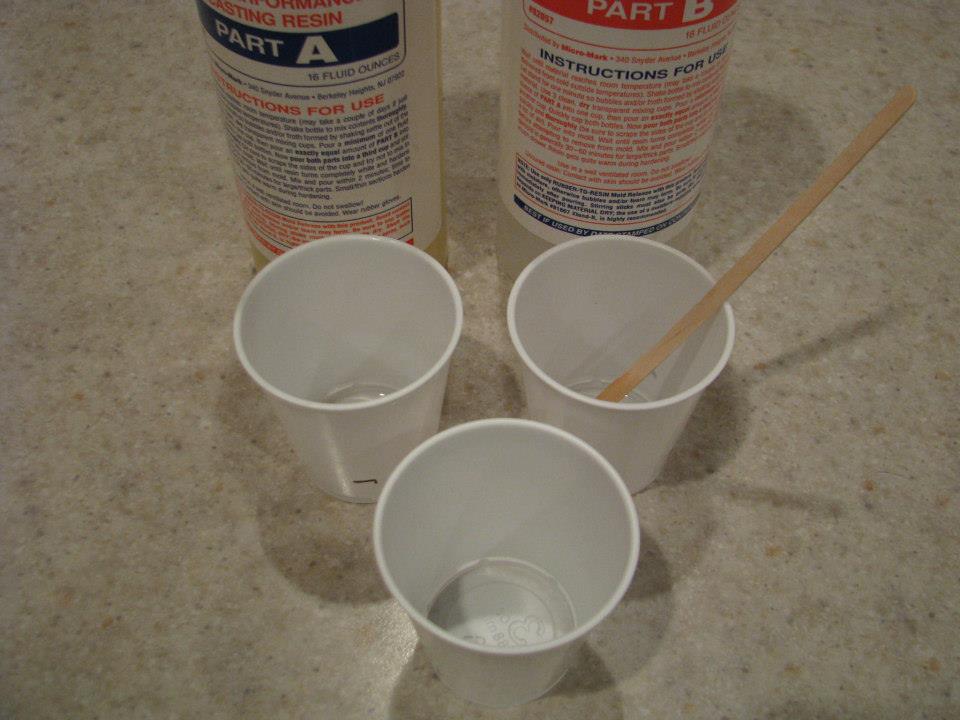

Pour the two part RTV into separate cups. Equal amounts are required. Then pour those into a third cup... stir and mix completely. You have time the RTV has a 4 hour pot life.

After it's completely mixed pour a very thin stream in the corner of the box and let the RTV flow around the mold master. Take your time here and pour slowly and high. *** This helps reduce bubbles ***

After it's completely mixed pour a very thin stream in the corner of the box and let the RTV flow around the mold master. Take your time here and pour slowly and high. *** This helps reduce bubbles ***

I pressure cast, so I also have to use pressure when I create the mold. If I don't use pressure when creating the mold my resin casts will have a bumpy surface when they are removed from the mold. I put the mold in and let it cook for about 4 hours.

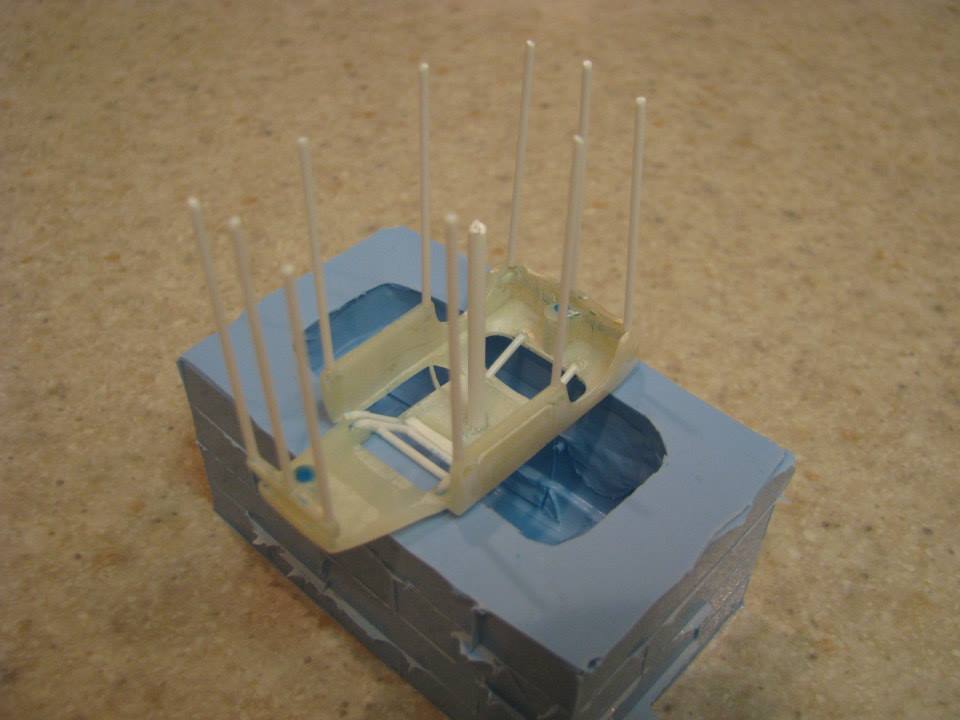

After about 4 or 5 hours I remove the mold from the pressure pot. I then remove the clay and the mold master from the female mold. I then clean up the mold master and add some rods which will create the vent holes to allow the air to escape when pouring the resin. I pour the resin in the larger center hole which is the lowest point in the mold. The resin then goes into the mold at the lowest point and works it's way up pushing the air out as it fills the mold.

The next couple of pictures I will use a substitute picture but the principles are the same. Take your newly created female mold and with an Exacto knife cut your mold alignment keys. Now insert the mold master back into the female mold and spray with mold release. Mix some more RTV to pour the male part of the mold. Important: spray mold release into the female mold

After spraying the mold release in the female part of the mold, I pour my prepared RTV into the female mold.

When everything is complete you now have a mold to do your casting.

Now it's time to mix and pour the resin. Unlike the RTV I have to be alot quicker because the pot life on the resin is about 6 minutes. That means I have to mix, stir, and pour the resin and then get it into the pressure pot and pressurized in about 5 minutes. I usually mix and stir about 1.5 minutes, take a minute to pour, and then 2 minutes to get it to the pressure pot. When you do this the firs couple of times make sure you have everything prepared before you start. Note it is important that you mix the resin completely.

I leave the mold and casting in the pressure pot a good 40 minutes before removing. And then I let the mold rest for another hour before removing the cast from the mold.

And there you have it one Avanti modified dirt racer!!

RSS Feed

RSS Feed